Protect The Tubes Just Like The Connections

Arnco’s Heat-less Welding Solutions allow you to hardband on tubes of drill pipe and tubing to protect the most vulnerable areas from wear.

Why Hasn’t this Been Done Before?

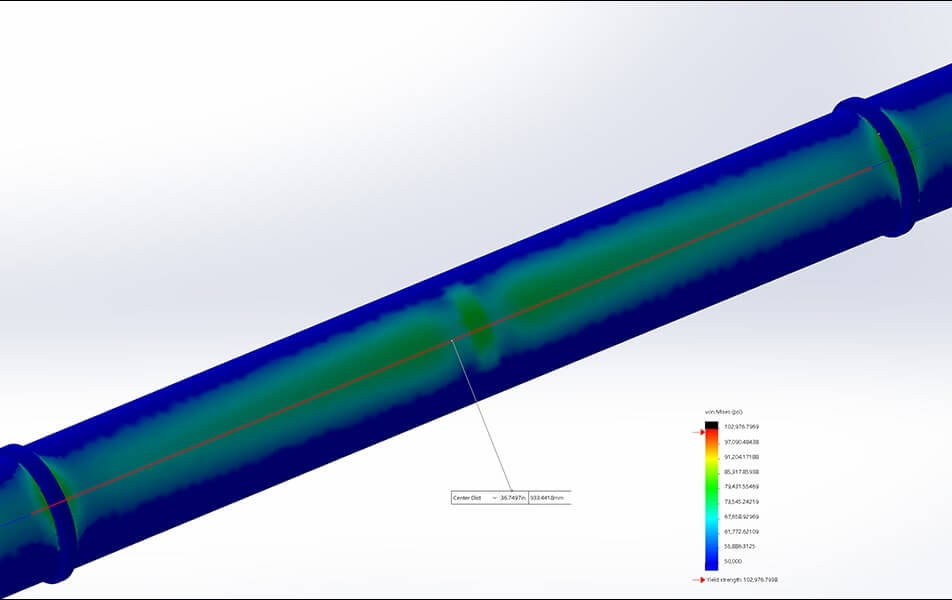

Everybody knows the tubes wear just like the tool joints, but no good solutions have existed to protect them. In the past, everything has been tried from composites to odd alloys, but none of it has worked. The answer was easier than anyone imagined: just weld the hardfacing onto the tube itself. This idea was ignored because it was universally accepted that the tubes are too thin and welding on them would damage them. But with Arnco’s low heat input welding process, Heat-less Welding Solutions (HWS), this is not the case. The tubes retain their manufacturing properties even after being welded, and the hardbanding doesn’t spall off or crack downhole.

Tube Body Wear Pads

For more information about drill pipe wear pads, download our Case Study

Tested and Proven

Before ever putting any pipe with hardbanding on its tube downhole, Arnco performed extensive testing to prove that the material properties don’t change. Once this was clear, Arnco performed downhole field trials to prove the hardbanding wear pads would stay on the pipe and not crack. Now, months later, Arnco has completed many downhole field trials with hardbanded drill pipe tubes in different formations with absolutely no issues.

How Does It Work?

Revolutionary Benefits:

Increase Lifespan

Keep drill pipe and tubing in the hole longer, by protecting its most vulnerable areas

Save Money

Don’t buy new joints when you can protect your existing pipe at a fraction of the cost

Protect the Casing

Protect the drill pipe and the casing, with Arnco’s casing-friendly hardbanding applied on the tube body

Reduce Risk

Work safely with a computer-controlled welding system, with less room for human error

Embrace the Future

Use the same advanced welding technology in the oilfield that SpaceX uses to build rockets